With more and more people use our tube & pipe laser cutting machine. We strongly recommend that you read the following procedures before operating the laser when you use the laser series .

1.Tools

For cleaning a fiber connector you need the following materials:

(1) Power-free rubber gloves or fingerstall

(2) Lint free optical cleaning wipes and/or swabs

(3) Ahyrous ethanol (Optical level , pure >99.5%)

(4) Compressed air (oil free,water free)

(5) Microscope

(6) Light source

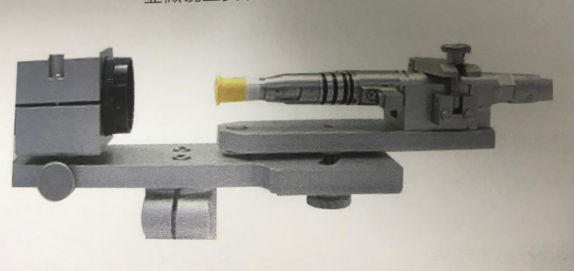

(Tube & Pipe Laser Cutting Machine Fiber Connector)

2.Operating Procedures

Cleaning and maintaining according to the following procedures:

(1) Switch off the laser power, and place the key switch on position of “OFF’’

(2) Remove the back outer protective sleeve and leave the white inner cap on and clean the fiber connector exterior with optical cleaner , wipe it with a clean optical wipe and dry it with compressed air.

(3) Place fiber connector in the holder of the microscope, remove the white inner cap from the connector.

(4) Focus the microscope onto the connector surface so that the protective lens can be seen clearly from the microscope.

(5) Check the surface carefully. If some contamination is visible on the surface , cleaning is necessary:

1. Put a few drops of alcohol onto the lint free swabs and throw away the excessive alcohol.

2. Place the swabs on the dust via microscope.

3. Cleaning the dust carefully, and move ti the edge of lens.

4. Repeat these cleaning steps until all contamination is removed. Take a final check under the microscope.

(6) Reinstall the inner cap and the outer sleeve onto the cleaned fiber connector.

(7) Take out the cap and sleeve ,then connect the fiber connector with cutting head quickly and fasten them.(Place the cap face down on a clean surface or a lint-free wipe)

Please make sure of the daily inspection and cleaning for the high efficiency pay attention to every possibility of causing an accident.We hope you will have an excellent user experience in LX Tube & Pipe Laser Cutting Machine .

( Tube & Pipe Laser Cutting Machine Fiber Connector Inspection and Cleaning Guide)

This article is from :www.lxcuttingmachine.

Mapa del sitio

Mapa del sitio